Reassembly:

The boards go back again quite easily and the connector pairings are fairly obvious. Although there are several instances of the same connector type, they are mostly only partially populated so even a blind idiot can work out the correct connectors to mate. It's possible that a fat and stupid idiot might make a mistake but that's another matter.

I have a 110V isolation transformer already set up in the garage to power some of the Mercan tools I brought back from Canada and I have a bench PSU that should suffice for the 24VDC supply. So I wired up some cables for each and connected them up.

First I cleaned up the cable glands. Wasn't strictly necessary but I couldn't help myself and it only took 5 mins. A bit of Gunk and some hot water did the trick:

Box back together, front panel back in place and connected to the terminal block:

Back on the main assembly and wired up, ready for action:

Compressed air:

Now I need to get some compressed air to it. As ever, pipework is a bloody fiddle - everything has to be the right thread, diameter, fitting type etc etc. Naturally I didn't have anything suitable and even the ones I have are BSP, while I suspect the Mercan fittings are some local flavour. This is the sum total of my compressed air fittings. And I have a combined regulator / oiler that has some potentially useful adaptors on it.

Tried a few things but ultimately I needed some 8mm plastic pipe, which I simply don't have. Had to make an adaptor piece from steel and hold the connection in place with cable ties. I drilled this out and soldered it into a std PCL quick fit connector.

Ready to go!

The arm swings in and out. The claw works using the manual control on the front panel but doesn't seem to do anything when the arm is doing its business. I don't know if this is normal. If so, the controller will have to take care of the claw in addition to moving the carousel, arm etc.

So here we are. I'm holding the claw closed manually so that it doesn't drop the toolholder. Otherwise it seems to be behaving:

The thing seems to have survived being taken apart and put back together again.

Geneva Mechanism:

It just hums when I press the switch. No movement, so something's not right. Ah, the fat stupid bloke had been busy in there when I wasn't looking and didn't connect up the motor running cap. I noticed that the motor had 4 wires and stupidly thought it was a universal motor. How dumb - an induction motor is much better suited to operating at a reasonably constant speed.

Seemed a good excuse to take the Geneva mechanism apart and give it a clean up / run my pork pie over it.

Here's the motor - very simple, being an induction motor.

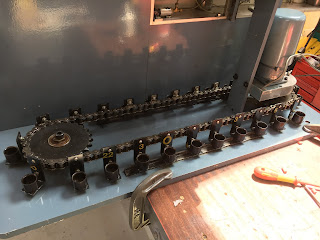

The baseplate cleans up nicely with the motor and carousel chain thing out of the way

Wheel back on. It has an eccentric for tensioning the chain.

There's a needle bearing under the motor end.

After cleaning up, the Geneva mechanism seems to be in pretty reasonable condition.

Microswitch back in, mechanism greased up:

All back together again. Works nicely.