This was the overall machining sequence:

- 3D adaptive clearing with 20mm YG-1 rougher (done)

- 3D adaptive to clear up with 9.5mm carbide (actually 3/8") end mill

- Bore out the counterbores for the cap head fixings with the 3/8" end mill

- Drill out the clearance holes for the cap head fixings (4mm drill)

- 3D contour to clean up the taper bore with BP300 indexable tool (0.8mm radius) using fine stepdown

- 2D chamfer to clean up the top edges (1/2" carbide tool) - where the tool can get in.

Also printed out the setup sheet which summarises the operations, tools, stickout etc for each step as well as a nice piccy of the setup. Blogger doesn't make it easy to post a PDF, so here it is chopped up into 3 JPGs:

It has to be said that I may have been a bit aggressive with the feed per tooth and optimal load for the carbide cutter, as it chattered a bit on the way around. However, that's probably not a surprise given that I pretty much used the manufacturer's max values for the cutter despite my machine being a bit long in the tooth. Next time I'll reduce the feed per tooth from 0.1mm to perhaps 0.05mm and the optimal load from 3mm or so to 1mm. But the finish is not bad and the tool itself was fine.

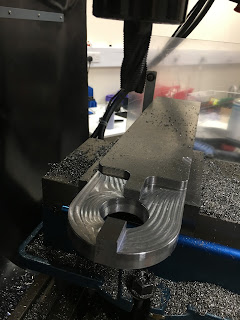

I reduced the feed rate for the boring operation using the same 3/8" end mill. That went very nicely without any need to pause to clear the swarf, followed by drilling the 4mm pilot holes for the screws. Now The Startled Man has his (startled) eyes!

The 3D Contour cleanup of the taper bore went well, although the 0.8mm radius insert is a bit small to get a decent surface finish. I should try to get some larger radius inserts. The Mitsubishi BAP300 tool body came with some 3mm radius Sandvik inserts but it's clear that they don't actually fit properly. Hmmm.

Finally, the 2D Chamfer was uneventful. Given that this is a carbide tool, I suspect 600rpm is bit on the slow side. I forget what happened but when I worked out the speeds and feeds I probably did them for an HSS tool. I've changed the default settings to 0.05mm per tooth and 5000rpm for next time. That sounds more like it....

After a bit of deburring with a half round needle file, it looks fairly reasonable. The tools are a good fit in the bore and against the dogs. I should probably smooth the bore off with some sandpaper - but only to improve the surface finish and avoid damaging the tools.

And here's the evidence that I retain a full set of intact tools afterwards!

Even Tool 13 (3D touch probe) remains intact. Incredible.

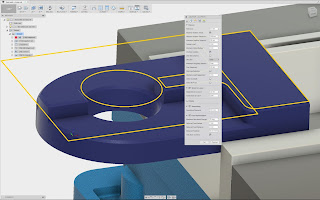

The finishing touches will involve making up the extension piece (amber) and foot (red). They hold the toolholder securely in the fixture while you nip up the collet chuck with the spanner. It should look like this, albeit without the garish colours:

The plan is to hold it in the orientation shown, either in the bench vise or fixed to the edge of the bench or machine table. There will be some form of finger screw (not shown) through the foot to secure the end of the taper while the graunching is being done.