Explained in Wikipedia(?)

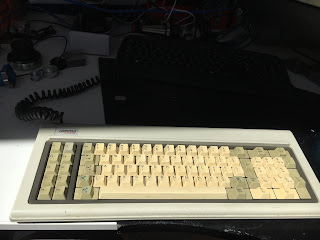

Disassembly and cleaning / retrobrighting:

Tool for removing the keys, made from shim steel:

All off:

The keys are both grubby and browned off:

I cleaned these with washing up liquid, then let them sit in 12% hydrogen peroxide with a spoonful of "oxy" washing powder. They were in broad daylight (and heat) on the 2 hottest days of the year here so far.

Foam and foil replacement:

Now, I have to remove all of the perished "foam and foil" pads:

Quite a PITA to remove the little disks at the bottom of the opening. I used a scalpel:

A week later, the replacement "foil and foam" pads arrived from the US. Although they only cost $25, I'm paying 2/3 that again in VAT, by the time the UK postal service has helped itself to £8 in "handling fee". At that price. the handling should include a "happy ending". Fuck 'em.

It was a royal PITA getting them seated properly. There are 4 little fingers that you must get the lower disk to click past. I used a scalpel again.

Quick clean of the PCBA pads with IPA. The pads appear to be electro tinned at best. Not silver (probably a good thing) or nickel.

Almost back together:

Done. Looks a lot better now but not artificially so.

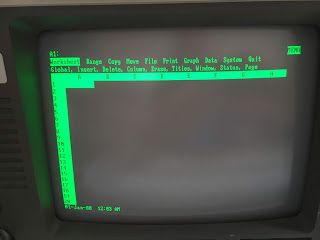

Rebooting with the repaired keyboard:

Yes, I simply reassembled everything and powered it up. It's all very well trying stuff out step by step but in this case, it was simply a matter of the pads being fucked and, as I was pretty certain I'd done a good job of the replacement process, it was bound to work surely?

But does it work? Yes, every key produces what it should on the screen. Phew!

On the Western Digital Filecard 30 (30MB hard disk - whoooaaarrr!), I can see a few familiar programs, such as Norton Utilities:

Lotus 123:

Norton Commander:

And there's also WordPerfect 5 for what it's worth. Here's what Norton's System Information tells us. I have the full 640k of RAM(!!!!) and am running DOS 3.31

Although the internal Filecard HDD appears to have DOS 5 on it, the machine won't boot from it. I don't recall its history but it appears to have ended up in an Elonex 386 (possibly 486) machine after its initial duties in the original Compaq Portable, judging by the QEMM386 Memory manager entries in the config.sys file.

Next - try to make the Filecard bootable (command.com, FDISK etc). It's all a bit hazy after all these years but it will come back. I still have the original Norton's DOS guide and Norton Utilities books from back in the 80s / 90s.

I've got some useful support from the retro PC forums.