Having got the spindle running and not being quite certain I want to tear the spindle apart again (yet?), I'll move on for now.

Next on the list is the hydraulic pump which will be needed to operate the turret and the tailstock. I've wired up the Yaskawa drive (1.5kW GA500) and so far I've managed to have wired up most of the control, so there's a chance it will simply work when I power it up.

Obvs I don't want to crank it up to full speed on a completely untested machine, so I will start at a low speed and see what happens. For one thing, there's a 50% chance it will rotate backwards. That should simply drive air back through the oil pickup - hardly the end of the world.

Yaskawa DriveWizard Industrial:

Previously I installed and tried out the DriveWizard smartphone app which connects via USB On The Go (OTG). Or it's supposed to. I coughed up (about £3) for an OTG adaptor to plug the slave end of a std USB cable into the GA500 so that the app could use the smartphone as a USB host. That turned out to be a waste of time and money, as it refused to find the drive. Bizarrely for a new product, the GA500 has a mini USB connector - I'd have expected a micro USB perhaps but hey, at least I have a wide selection of cables to choose from.

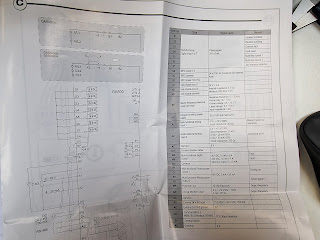

DriveWizard Industrial is a PC program that uses a more conventional USB cable to talk to the GA500. The GA500 is the slave and the PC is the host - very conventional. Furthermore, it actually seems to work. There's a setup wizard that will run you through the basic configuration but when I checked the default parameters, they were pretty much spot on. It had even been configured for 50Hz motors. The motor nameplate parameters are shown in this post from a few weeks back.

The operator panel runs from USB power, so you can configure and program the drive without the need to apply mains. Obvs you need to apply mains and enable the drive remotely before anything will move. Once connected up, there's a virtual operator panel that allows you to enable the drive and set the reference frequency. Bizarrely perhaps, this all worked out of the box.

Did it work then, Fatty?

Well yes and no. Initially the motor ran backwards at about 8Hz (around 240rpm) - this was always a 50:50 chance. The bubbling sounds rather gave that away. So instead, I ran the VFD in reverse so that the pump ran in the correct direction. After a short delay, the pump primed and started to build pressure. Then the feed hose started pissing oil out over its entire length, from the pump all the way along the drag chain to the turret. Fuck. So basically the hose(s) are completely perished.

If you look closely, you can probably see the pools of oil all over the rear of the machine...

Luckily I was able to stop the motor quickly and the oil spillage wasn't completely overwhelming. But now I'll need to remove the feed and return hoses and get some new ones made up. Bollocks. I wasn't expecting such a catastrophic failure of a hydraulic hose so hadn't even thought of testing it - compressed air might have shown up the issue. But at least nobody died on this occasion.