I had to remove the Z axis ballscrew assembly to drop the quill / spindle assembly for inspection. It's not too much of a ball ache to do this but it does require the power drawbar assembly (including the drawbar itself) to be pulled aside There's a short extension piece that screws on to the top of the spindle (left hand thread!) and holds the drawbar captive. Unless it is removed, the quill assembly won't drop out of the drive splines. I think this extension is there to forcibly eject the bar if the toolholder is slightly stuck in the taper.

And given that I found the X and Y axis ball bearings needed to be replaced, I thought I might as well just strip the Z axis ballscrew assembly down and see what is going on while I was at it. I had no desire to remove the ballnut from the ballscrew as such (I already know there is almost zero backlash there) but there is a pair of back-to-back angular contact bearings that I haven't inspected. If they need replacement, this is as good a time as any. I don't want to be fannying about with this any more than necessary in the future.

It's obvious that somebody has been in here before. I suspect the current bearings are not the originals but if so, they are at least good quality Japanese replacements. Once cleaned of the original grease, the bearing surfaces looked absolutely pristine. No need to replace anything there, just regrease and reassemble.

The drive pulley was a bit of a bugger to remove and needed a pulley puller in the end. There was a fair bit of green Loctite holding the key in place and the pulley on the shaft.

There are some odd looking marks on the face of the yoke. I suspect these are the result of years of movement between the yoke and the quill. Tellingly, the main witness mark extends downwards (gravity etc) from the top bolt hole. Material has been removed from this area, presumably by abrasion.

There are also clear signs or abrasion on the side of the yoke but this is between the yoke and the slot in the head, so most likely caused by air-borne debris.

I dressed the mating surface between yoke and quill to ensure that the contact area is around the circumference rather than the centre by scraping away some of central area and checking with some bluing and rubbing. It's far from pretty but I consider it a slight improvement. At least this way, once the bolts are tightened, there should be little chance of the yoke rocking. However, if it is possible for the yoke to slip axially in the quill, this won't fix the problem. Similarly the mating surface between the top bracket and the head:

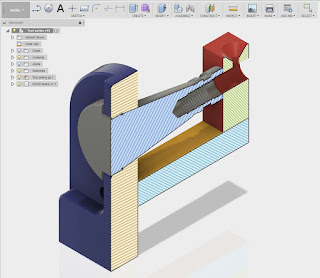

Finally, I modified the upper bracket that holds the ballscrew thrust bearings. Originally it had 2 x M8 bolts to secure it and a couple of dowel pins to locate it right to left. Vertical alignment is by an accurately machined slot that provides a tight fit to the bracket body. I drilled and tapped the dowel holes in the head to M8 thread and opened up the holes in the bracket.

- Drill bracket holes to clear the tapping drill (7.0mm)

- Fit bracket and drill the dowel holes in the head out to 7.0mm

- Drill bracket holes to 8.0mm - to guide the M8 tap

- Fit bracket and tap the holes in the head M8

- Drill bracket holes out to 8.5mm to clear the M8 bolts.

Bit of a PITA but with the use of an edge finder and the DRO on my manual mill, I was able to place the holes quite accurately.

Some careful positioning of the bracket was needed to ensure the holes in the bracket were aligned with the holes in the head. Not much point using the bracket as a guide if it isn't in the right place.

Some careful positioning of the bracket was needed to ensure the holes in the bracket were aligned with the holes in the head. Not much point using the bracket as a guide if it isn't in the right place.

The top bracket is now secured with four high tensile M8 bolts, each torqued down to 25Nm.

But what is causing the yoke to move in the first place??

I reassembled the quill into the head and found that the closer it gets to the top position, the harder it becomes to move. And once it's at the top position, it's actually pretty difficult to budge. I've noticed that the backlash is worse close to the top position. Using the trolley jack (without the handle) or a sash cramp, it's a real struggle to force the quill all the way into the head. It's perhaps no surprise that the yoke is struggling to move the quill without sliding about in its slot.

It's not easy to examine the bore of the head near the top end, although you can see there is some crud and possibly a bit of rust near the top. Worst of all, there is a nasty looking score at the rear of the bore. Sounds like a right old bodge but I took a strip of emery cloth and dressed it off. But I wasn't about to start sanding off the bore at the top where it seems to be binding. There's no burring on the spindle, so this must be the result of some debris or rust that got in between the quill and the bore:

Using an online tension torque calculator, it's simple enough to estimate the force between the yoke and quill resulting from the pair of M8x1.25 bolts at the 25Nm torque I applied. The estimate is 4.65kN per bolt ie about 9kN total force. With a fairly low coefficient of friction of around 0.2 (ground steel surface against ground cast iron surface), the max shear force before slippage occurs between the yoke and the quill (in the direction of the Z axis) will be of the order of (very approximately) 0.2 x 9kN = 1.8kN, or the equivalent of 180kg weight.

It's probably a bit of an oversimplification and a very rough approximation, as the ballscrew load is applied on the end of the yoke but if that kind of load is applied, I'd expect to see the yoke slip and I think that's what is happening.

What to do? I reassembled the whole quill / Z-axis system for now and confirmed that the lost movement is still present (there was no reason why it should have gone magically). I plan to reassemble the yoke to the quill finally, using some Loctite 638 gap filling adhesive. This should be suitable for preventing the yoke sliding within the relatively small gap between it and the mating slot in the quill. Unmating the yoke is a fairly simple matter of loosening the motor to untension the belt, unbolting the upper ballscrew bracket and removing the 2 bolts in the yoke itself. No need to actually extricate the assembly as such.

The stiffness of the quill in the head bore will hopefully ease up with use, since it must surely be the result of corrosion (humidity). I suppose I could create a short series of g-codes to cycle the head and help to bed it in.