Bollocks (again). I let The Stupid Fat Bloke continue with the 2nd and 3rd cams, so you can guess what happened. On this occasion, he got the 2nd one done then let his success go to his head. The result is that the 3rd part ended up with a 1mm wide shoulder instead of a 3mm wide one. And given that that shoulder takes a fair bit of the thrust load, it's a scrapper.

So let's make another. I should have made up 4 from the outset really. Here's the stock, turned down to diameter and length. As before, use The Shiz to place a centre drill hole, offset 0.8mm to give the required eccentricity:

Then set it up in the 4-jaw, ready to turn the eccentric portion:

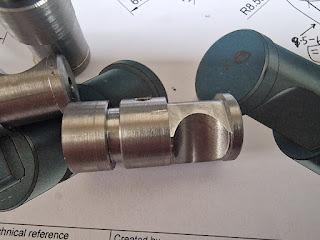

Sorted. You can see the one TSFB screwed up, second from the left.

Now to create the cylindrical feature using a boring bar. I need this to be 15mm diameter, so I'll drill some 12mm holes and set the tool to exactly 15mm before moving over to the cam bodies in anger.

Pretty close, given The function this feature supports:

I need to have some form of angular reference so that I can position the features consistently. They will be at 45 and 90 degrees to this reference bore, which is in turn 15 degrees from the point of maximum eccentricity.

I think I'm ready to machine the cylindrical faces:

Some careful setting up with the Renishaw probe and here we are:

Using some ground parallels and a vise stop allows me to place the other parts subsequently.

And there we have them.

Now I need to turn them 45 degrees so I can machine a flat. Here's my solution, using a pin in the reference bore and this digital angle gauge:

And finally, the flats are done. Looking good.

That's most of the main operations done now. It remains for me to machine the female square drive hole. I'm going to make this 8mm across flats, using a 3mm end mill. But that's for next time. I'd better not let TSFB fuck this up, as I have no spares.....