What's this about, Fatty?

Serious trouble on the UK Machine Tools Facebook user group again, involving a mouse, as ever. This time I've ended up with an 8" Kitagawa hydraulic chuck. These are the dog's bollocks as chucks go and although this is a rather old model, it seems to be in decent condition. Not bad for £200 plus £18 carriage.

Here's the chuck itself:

And yes, it even has an A2-5 adaptor plate (complete with fixing bolts), so it will bolt directly to the nose of my machine. What were the chances of that?

Might be fucked up inside but I can't see any signs of that. It appears to have been reasonably well looked after, apart from a few minor dings on the body.

And even better, it comes with a shed load of soft jaws (some new, mostly with a fair bit of life left in them) and a set of hard jaws in decent nick.

And even better still, it comes with 2 sets of tee nuts. A complete starter kit!

So why the long face, Fatty?

Well, is a "collet closer", as provided on the Tree the same as the "hydraulic drawbar" expected by a Kitagawa chuck? Well, for one thing, it only needs to pull on the (3J or 5C) collet, whereas these chucks require positive push / pull actuation to open and close the jaws. This isn't just required to tighten or loosen then jaws but allows for both external and internal gripping.

The Tree collet closer isn't well documented but it has 3 fingers (levers) that compress a set of Belville (disk) springs to release tension on the collet closer drawbar. Releasing them causes the springs to tension the drawbar and pull on the collet. Is that it? If so, then I've wasted my time, money and excitement here. I could be looking at a chuck that fits my machine but won't actually function....

NO - LIGHTEN UP!! These springs are only provided to define (limit) the tension on the collet drawbar when the collets are tightened. It does this by compressing the springs by a controllable and consistent travel at the end of the (tightening) drawbar movement.

We can estimate the movement that the Tree collet closer generates on the springs at the end of travel. The fingers provide a reduction ratio and the initiating movement is caused by sliding a conical body up inside the fingers.

Here's the drawbar with the conical feature and one of the actuating fingers. You can see the range of movement from the witness marks. The entire drawbar is moved axially by the actuator, by something approaching 30mm or so:

Here are my fag packet calculations, which estimate around 2.3mm of axial compression (compression), assuming zero clearance at the start of movement.

The collet tension is intended to be this movement times the spring coefficient of the combined stack of Bellville springs, whatever that is. The Tree manual simply tells you to adjust the engagement of the drawbar with the collet by screwing it in or out "until the desired gripping force is obtained". Very helpful. However, in my case, the Bellville springs play no part in the operation of the Kitagawa chuck and I don't plan to play with collets at this stage - perhaps later, once I can find a (replacement) adaptor to run 5C collets in the 3J spindle nose - you may recall that The Stupid Fat Bloke machined the original one out, as he was unable to remove it without risking damage to the spindle and/or bearings.

So, will it work on the Tree?

Pretty convinced it will. With the later(?) version of the collet puller / drawbar actuator used on my machine (as opposed to the one shown in the manual), I seem to have a pretty decent range of movement, with the ability to apply both tension and compression force to the drawbar, said forces being controlled by the hydraulic pressure from the pump.

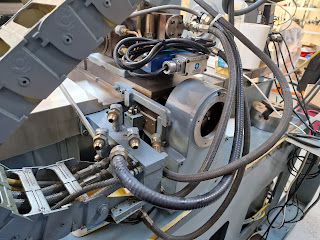

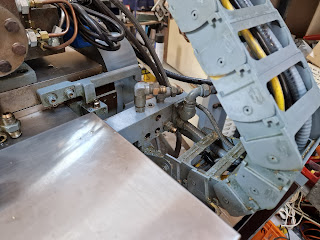

There's a big fuck off bearing here that handles the thrust load. I removed it from the drawbar earlier (during the initial dismantling) but the circlip on the drawbar shows where it sits. That bearing (shown here) is moved in and out axially by a hydraulic piston and yoke:

The bearing doesn't sound completely happy, so I will need to obtain a new one. However, the piston travel seems to be ~20mm (I saw 30mm above, mind), judging by the witness marks on the push rod. The mechanical advantage (lever ratio) is 1:1, so that will result in around 20mm of movement of the drawbar. Is that what the chuck needs?

And indeed, the required stroke is ~16mm at the drawbar, resulting in ~3.7mm radial movement of each jaw. Sounds as if the chuck gods have smiled on us here.

Not sure why but Table 5 suggests ~2mm stroke. Whatever. As long as we give it the required drawbar movement and force, we will get the intended operation.

What about the drawbar - does it fit?

Does it shite. Of course not, as it's intended for a 3J collet or a 5C with the supplied adaptor. Both the drawbar and the chuck have female threads of course. So I will need to make up a short male-male adaptor that mates with the drawbar and the chuck.

Seems the current B08 chuck has an M60 x 2.0 female thread, although mine measures at M50 x 1.5. No problem, as I will make it up on the Bantam which doesn't care. If anything, an M60 thread might have been a bit of an issue with my A2-5 spindle nose. The current range uses an M55 x 2.0 for the A2-5 (6") version.

Seems that a 3J collet has a 1.988"-20 thread. So that defines the threads. It's helpful to see that the 2" thread is pretty close to the 50mm one. All I need to complete the dimensioning of the adaptor is the length and diameter(s)....