Came out well but at some point I'd like to refit the gates without a resulting 12-18" gap which would rather defeat the point of having a gate in the first place.

I'm not about to replace the gates or chop them up to any degree. Instead, my cunning plan is to fit spacers between each gate and its pillar. But how big? And how damned fiddly? I hate unnecessary work, so a bit of planning is usually well justified.

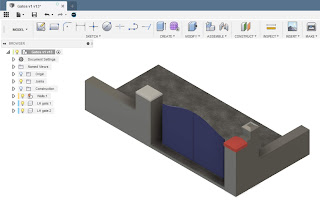

Was actually pretty quick to measure up, create some sketches and generate a 3D model in Fusion 360.

But it allows me to position the gates symmetrically in the gap and double check the required gap at each side. With the 40mm offset to the axis of the existing hinges, I can see I need steel flat stock of about 180mm width at each side. The height is about 1.35m, so a standard 3m of black steel should suffice.

I'm sure it isn't the cheapest place to buy a length of hot rolled (black) steel but I have no time to start hanging around blacksmiths and fabricators trying to pick something like this up myself.

I've ordered it from metals4u.co.uk It'll sting me for just shy of £130. On the up side, this place is within spitting distance of the place of my first employment on Sandbeck Way in Wetherby. Back in the 80s and early 90s, Farnell Instruments / Farnell Advance had a R&D / factory site there. Long gone now but I knew the place well after 11 years.

I'll make up 4 large eye bolts that will span from the existing hinges to the existing holes in the gates. Then these 180mm x 6mm strips will fill some of the gaps between the gates and the pillars.

If this turns up before Xmas, I may get some fabrication done - cutting, welding, grinding and bodging. I'll have to see if I can get them galvanised afterwards, assuming I ever get them finished of course....

Nice.

No comments:

Post a Comment