This is the nameplate on the 4kW Chinesium motor. It's a 2 pole / 3000rpm machine and is about the biggest motor you can get for 230V operation. It's no coincidence that the 4kW VFD is also the biggest you can easily get for a single phase 230V input VFD. The original spindle drive was rated around 5HP, so I am not far off meeting / slightly exceeding what was originally fitted.

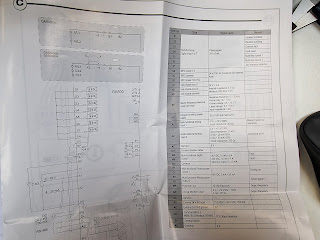

The Yaskawa GA500 is almost ready to go out of the box. I've even wired up the control IO correctly. Will it simply work? I could just try and find out but I'll enter the correct motor parameters etc and do the job properly by running the autotune feature.

That was pretty simple. The only challenge was figuring out how to start the autotuning process once the basic parameters were set up. The manual somehow overlooked that basic information. For future reference, the autotune menu is selected as "ARUN" and the parameters are the T-XXX set. And to initiate autotuning, you select the last parameter ("RUN 10") and hit "RUN". Silly me for not being psychic yet.

So the thing pretty worked out of the box, wiring and all. The only minor isse being that the motor spins backwards. No problem, I can simply swap over any 2 of the phase connections, having randomly wired them up. There was a 50-50 chance of being correct and on this occasion I lost.

How does it run, fatty?

Well...... It's not deafening but it's making noises I'd rather not be hearing, not least having dismantled and rebuilt the spindle cartridge without seeing anything obviously wrong.

The tensioner pulley has made a few noises when I've been playing with it and it warms up after 5-10 mins of running.

It's vaguely possible that this could be a source of noise although I'm not massively hopeful. However, as I bought replacement bearings when I replaced the spindle encoder bearings, now is the time. Of we go...

Lots of gungey treacle in there. The outer races are contained by circlips and the inners are clamped against a bush.

Don't forget to replace the bush before refitting the second bearing!

There. All back together again.

Well - is that any better?

Hmm. Not really. It's good to have replaced the tensioner bearings but it shouldn't be making the kinds of noise it is. I'll try changing the modulation scheme in the GA500 in case it's some sort of electromagnetically generated noise. Again, I'm not hopeful but I'd rather rule that out before pulling the spindle cartridge out and removing the bearings for inspection and possible replacement.

No comments:

Post a Comment