Wahaay. Relieved but not surprised to see the Centroid team have thought this through and implemented the various variants such as:

- Internal / external tools (determines which X direction to probe in)

- Left handed / right handed tools (determines direction of cut ie toward / away from headstock etc)

- Drills, taps etc

- Direction of spindle rotation (in my case, CW for external tools and CCW for internal tools, which is the reverse of "normal" (ie manual) practice.

How is it all set up?

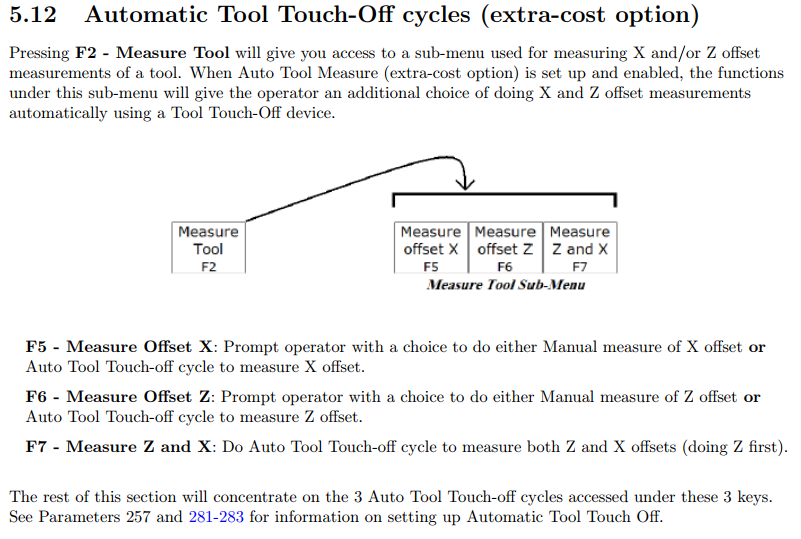

See Chapter 5 "Tool Setup" of the Centroid Lathe Operator Manual:

Setting up auto tool touch-off parameters in CNC12 Lathe:

With the "Pro" lathe licence, the tool probing is included although Swissi hasn't created a special "probe app" for the lathe (yet?). The setup is pretty simple and is easiest taken care of by the wizard. There aren't many things to set up. Once you have told CNC12 which input is the Probe Detect signal, the only parameters you can / need to set up are the stylus widths in X and Z and the "safety clearance" distance. That's only 3 parameters:

Running auto touch-off:

Fairly simple when you know how:

Uwe Mattern posted a YT video recently showing his setup with the DIYO probe and Acorn (Acorn 6 in his case, FWIW):

Mine pretty much does the same although I can't mount my probe on the spindle axis due to the constraints of the axis movements.

I have a spare input on Acorn, so got this set up and did some playing, using a bit of Bluetack on the probe tip ('cos it isn't designed for tool touchoff).

No video? It didn't happen!

Here's the most commonplace touchoff move ie a RH external tool. I know, I know - in my case, technically it's actually going to be a LH tool but let's keep life simple.

There. This gives me the confidence to know that my slightly unconventional machine setup should work fine with the Acorn software.

No comments:

Post a Comment