...and off we go.

Retrofitting 1983 Shizuoka AN-SB CNC milling machine, Bridgeport mill, Colchester Bantam lathe and 1982 Tree UP-1000 CNC lathe with modern controls - and other workshop stuff

Thursday, 17 August 2023

Chip time - let's do it - 16mm Autolock collet to JT1 taper

...and off we go.

Wednesday, 16 August 2023

Problemette with ER16 boring bar concept

I thought I had a neat solution for replacing the ER11 collet chuck adaptor. But there is a slight issue with this cunning stunt. As you can see, the main body has a through bore of about 8mm. That is somewhat larger than the 60 degree centre pip in the Autolock chuck which is responsible for the accurate radial location of the inboard end of the cutter / collet chuck. So the only way around this would be to create yet another adaptor that would sit in the end of that bore, with a centre hole for location.

This would be getting rather messy. Not only would I need to bore out that hole (to ensure it is concentric) but I'd also need to make up a mating part with a centre hole. All of those features would have their own tolerances which would stack up in the final assembly. I'm needing something better than 10um total runout at a guess, so this concept doesn't sound as if it would be worth all the buggerage.

Bingo!

At this point, I chanced upon a familiar looking component on the Arc Euro website. This is the exact same ER11 collet chuck adaptor that came with the speeder in the first place.

The only obvious difference is the rather large / clunky nut. Obvs the only sensible thing to do was to order a few of them. And yes, in the flesh they are clearly the same part:

- Set up stock in 4 jaw

- Centre drill, then support with tailstock

- Rough and finish the taper

- Thread 20tpi

Monday, 7 August 2023

More Fusion 360 buggerage

Machining the ER16 collet chuck:

Once I've received the ER16 collet chuck, I'm going to have to shorten the shank and machine the 20tpi threads on it, so that it fits in the speeder's Autolock collet nose.

Stupidly, I tried to create the thread within the Fusion 360 Design environment. This turned out to be a hiding to nowhere, as there's no way to specify a non-std thread, such as 16mm x 20tpi. You can only choose from a predefined pulldown list of standard threads:

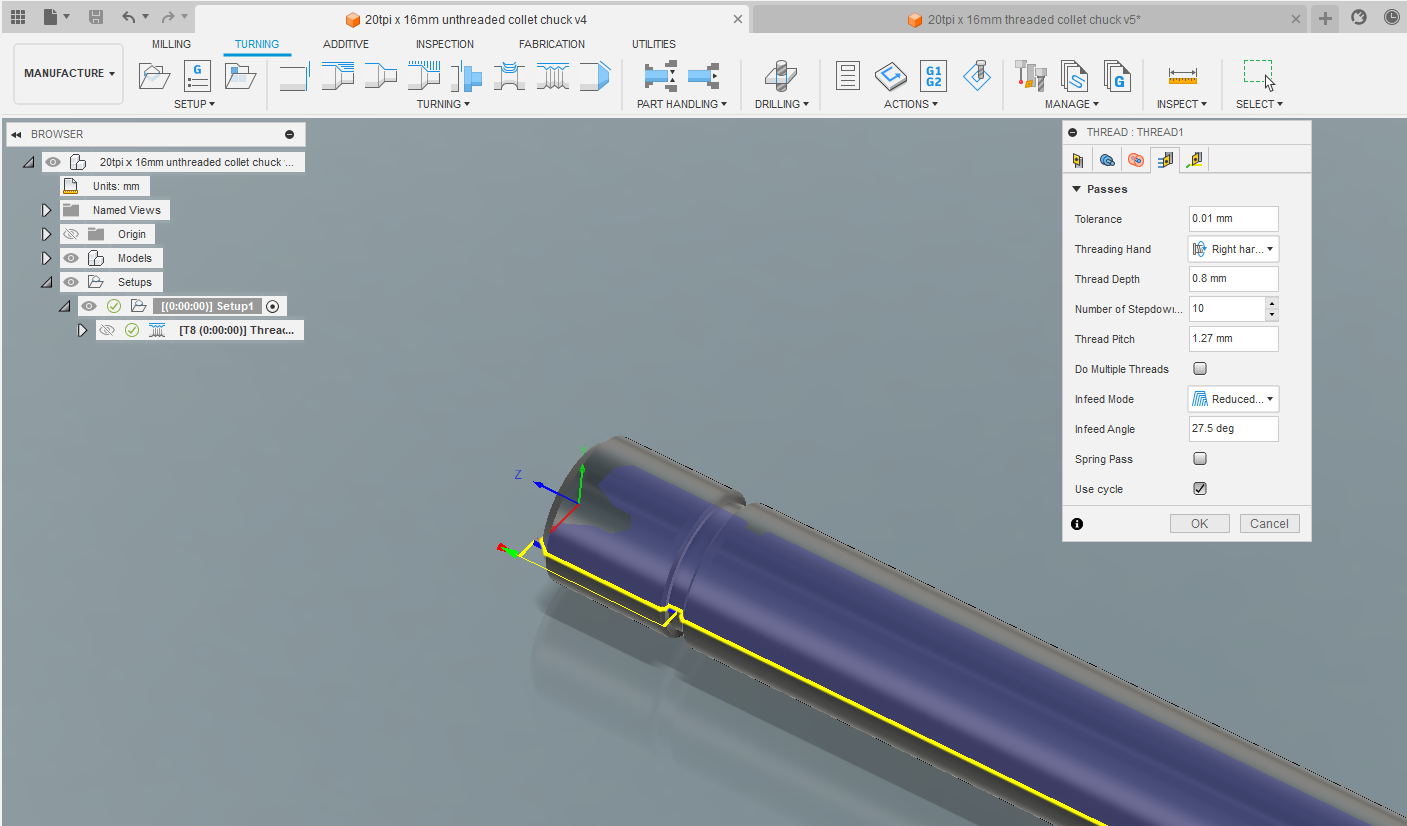

The way around this is to model the machined (unthreaded) blank....

The problem is that in this particular instance I want to be able to bring up the tailstock and support the end of the collet shank. This makes the LH toolholder a bit of an issue, as it would clash with the revolving centre. So ironically, having gone to the bother of creating the LH tooling, this is a case for a conventional RH toolholder.

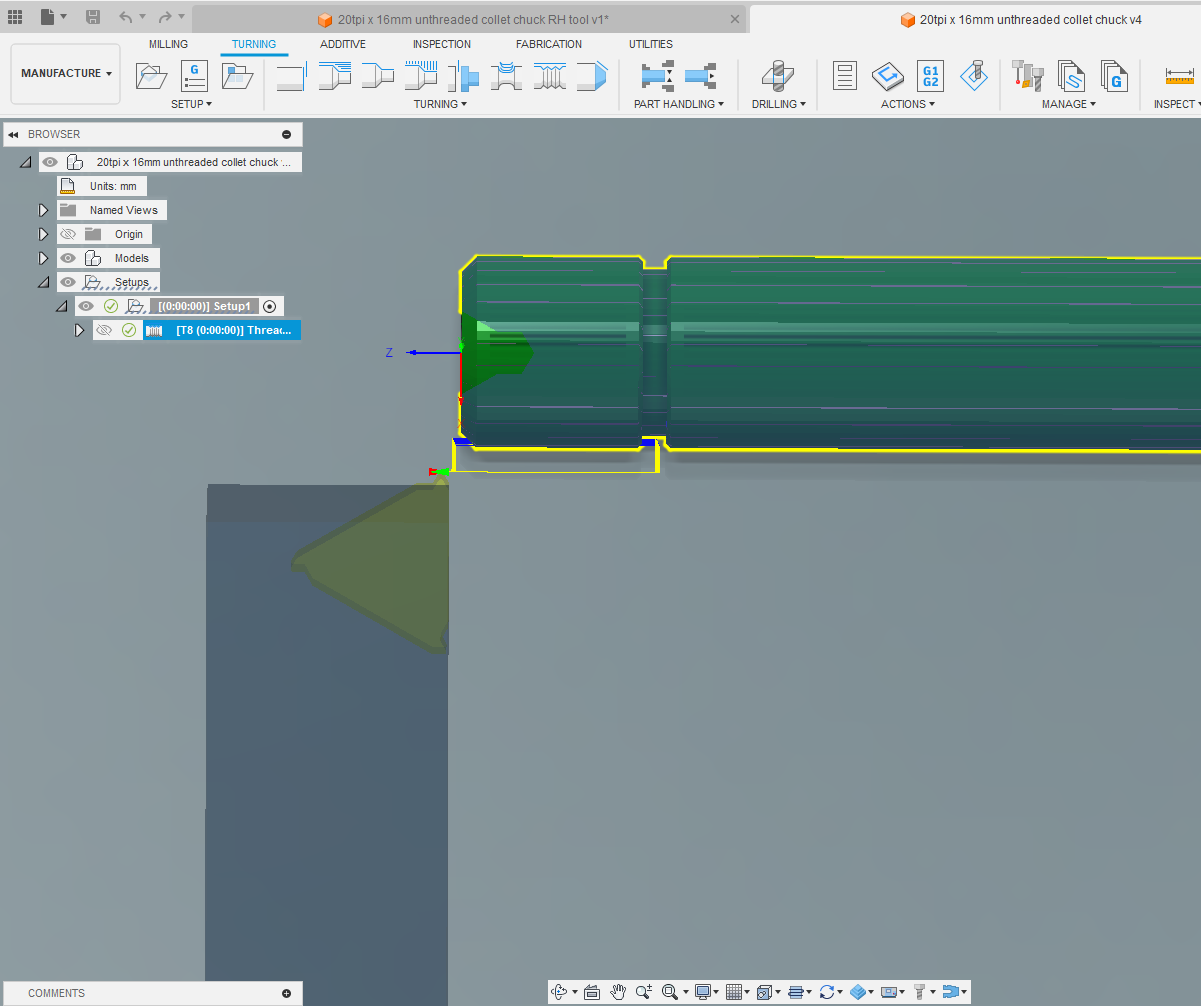

Try as I might, I can't get the tool to cut the correct axial portion of the shank using the default settings. It seems determined to only thread the first few mm of the shank, then continue out into the space beyond - where the tailstock would be. I can't tell you how frustrating this is.

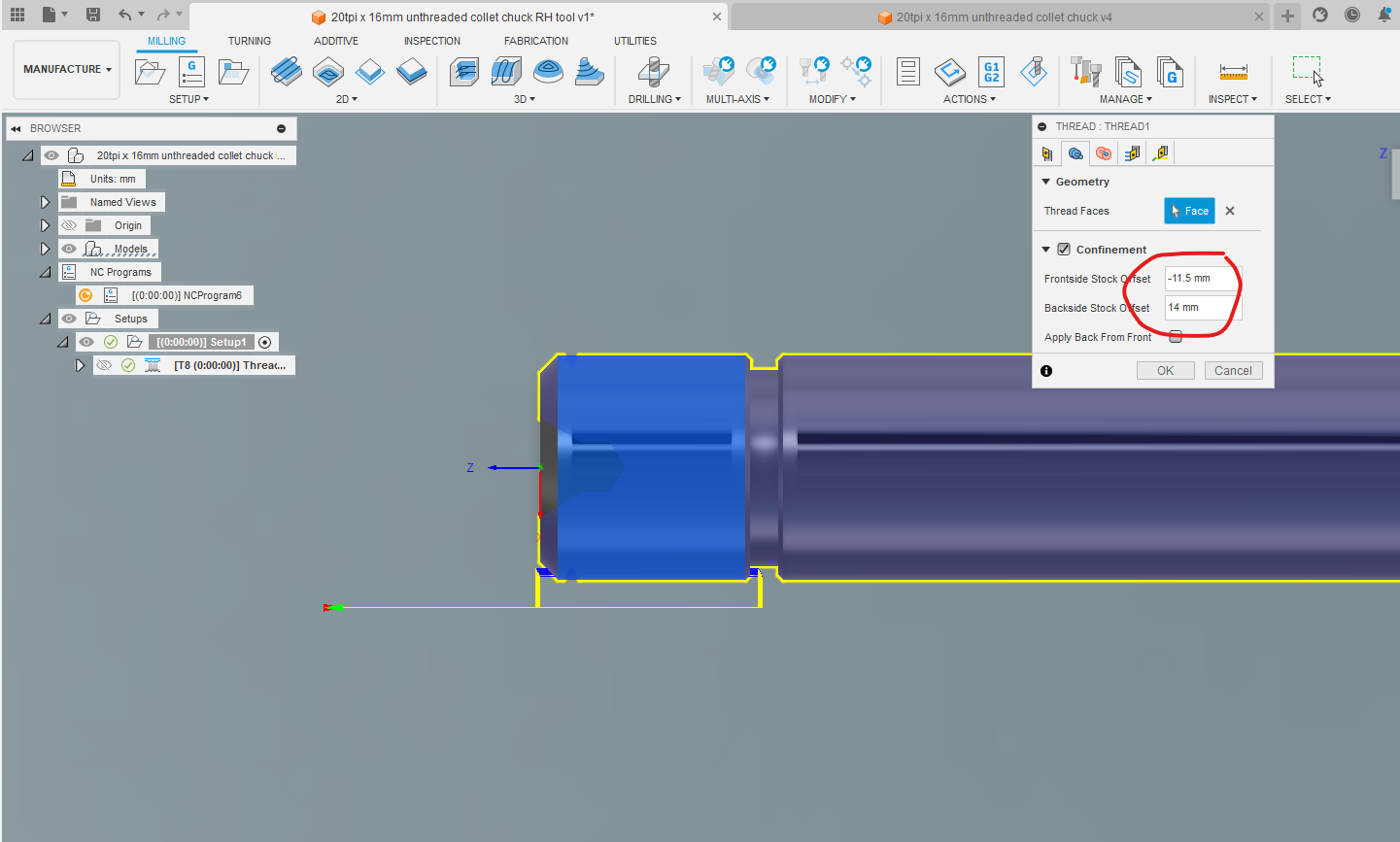

Finally, I was able to force the path to the correct axial position by playing about with the containment values:

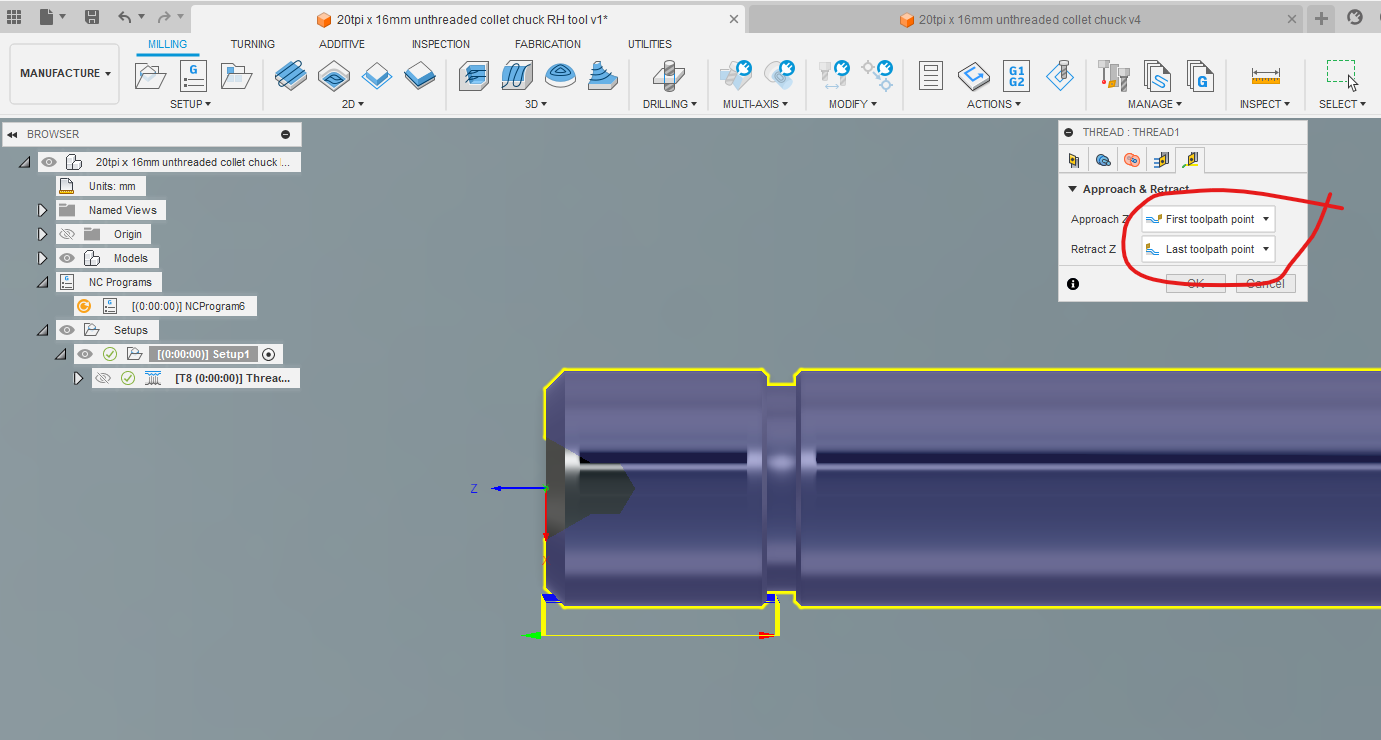

But even then, Fusion is trying to crash the tool into the tailstock during the retract move. Doh!! So I clearly need to fiddle with the retract distances as well.

And just to keep you awake at night, the simulation graphics show a LH thread, even though the rotation and tool direction are correct for a RH thread. This part of lathe CAM is clearly in a bit of a mess.

N15 M0 ;CHANGE TO T8 ON REAR TOOL POST

N16 T0800

N17 G54

N18 M8

N19 G90 G99

N20 M33

N21 G97 S500 M4

N22 G4 P1.

N23 G0 X20. Z-15.849 T0808

N24 G0

N25 G92 X15.494 Z0.051 F1.27

N26 G0 Z-15.795

N27 G92 X15.284 Z0.105 F1.27

N28 G0 Z-15.753

N29 G92 X15.124 Z0.147 F1.27

N30 G0 Z-15.717

N31 G92 X14.988 Z0.183 F1.27

Note that the feed value ("F1.27") is positive ie for a RH thread. This is finally starting to look usable.

Well "that was a couple of hours of my life I won't get back" etc. Thanks, Fusion team.

Friday, 4 August 2023

Checking out the speeder - was it worth it?

Hold on, Fatty. There's more space between the spindle nose and the end of the quill than you'd thought. So the speeder will still leave plenty of room for the reaction arm without any need for butchery.

End stop for drawer self closing damper

Que? We have a couple of these pull out spice drawers in the kitchen. They are 150mm / 6" width and are basically filling in a 30cm gap...

-

Setting up the servo tuning(?) software: Having spent a couple of hours yesterday pratting about with the PID controllers for the X and Z ax...

-

Right, so having gone through the motions with the X axis (cross slide), I should now be able to set up the Z axis (longitudinal) encoder an...

-

The bearing arrived as expected this morning. Took a few minutes to make up a 42 x 25.5 x 7mm thrust washer, then fitted the bearing and was...