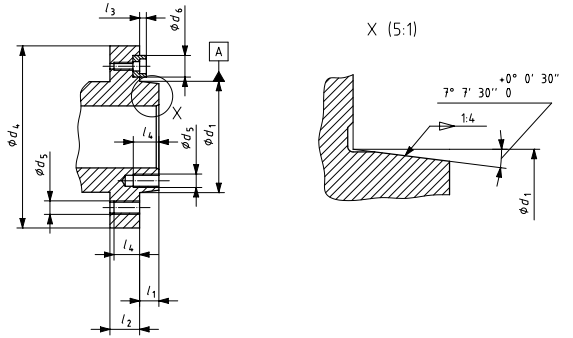

Trial fitting of the adaptor body to the Tree spindle nose reveals a problemette - the adaptor bottoms out on the taper nose before it seats on the actual taper. The nose seems to be longer than the taper bore.

- What's the problem here?

- Why have I only just found out?

- What can I do to resolve it?

The actual stickout from the mounting face of the Tree spindle nose measures at ~14.3mm. But the technical standard for the tapers states the stickout as 13.00mm. So the Tree's nose is too long!

The reason I haven't spotted it until now is due to the fact that I machined the adaptor taper on the Tree with the Vertex 4-jaw fitted to the spindle. I have avoided disturbing the chuck until the last possible moment. So it's only now that I have removed the Vertex chuck that I am able to do a test fit. And my CAD model was created from the BS ISO standard, not measurements taken from the machine. Doh.

All is not lost, apart from my temper for a few minutes. I can counterbore the adaptor axially by an additional 2mm to provide clearance for the tip of the spindle nose. As this will be a clearance (non functional), the concentricity and perpendicularity are not critical. I can do this on the Bantam. Still, it's fair to say this is rather annoying.

No comments:

Post a Comment