What up?

I'm sort of preparing myself to get involved with my 1967 Honda S800 coupe again. It's been salted away for the last 30 years (family, kids etc) and deserves to be brought back to life. Rightly or wrongly, I decided to replace the original quad carb setup with a fuel injection system. Nobody knows why - but either way I am some way down the road with it, having hacked the fuel tank about and fitted it with a high pressure fuel pump, so there seems to be no going back.

The main activity remaining is finishing off the airbox, ideally in such a way I can incorporate an air filter. The issue being that the original CBR600RR airbox clashes with the alternator.

Here's the intake side of the engine:

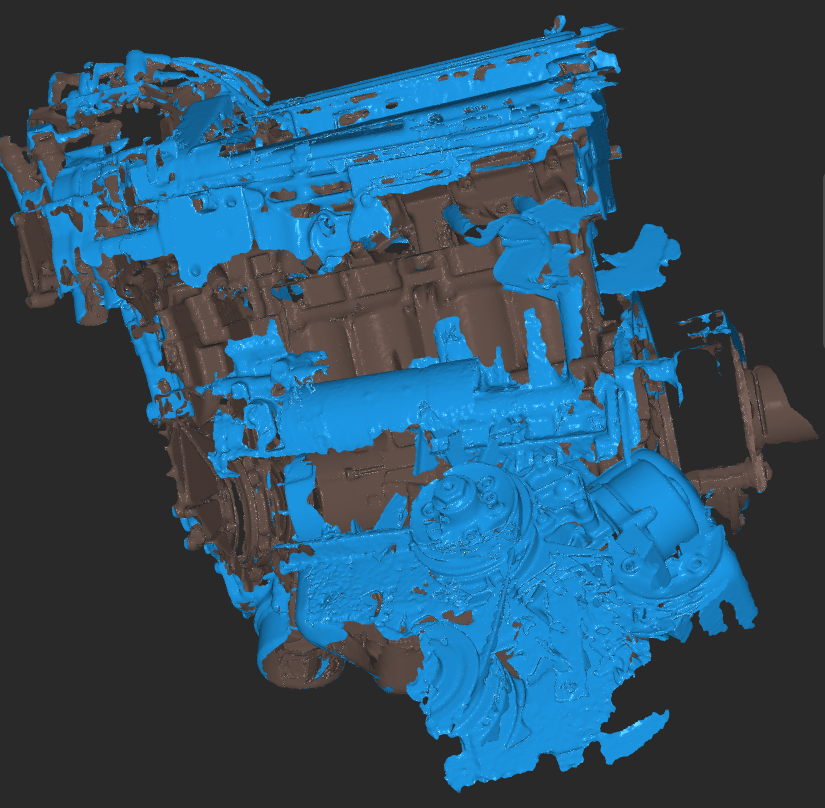

And after a few hours buggering about with the scanner, I've got a sort of result. Ish.

Hmm. Quite a few bits missing here. Here's what the scanning process looks like when you have parts that are small enough to fit on the (Bluetooth controlled) turntable:

The throttle bodies are almost recognisable here, but this is hardly a breathtakingly accurate model.

I seem to be stuck between 2 extremes: on the one hand, to get decent scanning (ie without losing "tracking" continuity), you need lots of features that the software can recognise and use to stitch together the hundreds of scans, yet wtih too many features, the software is easily overwhelmed. I seem to have fallen foul of the latter.

Conclusions:

For now, I will conclude that these scanners are good for scanning smallish, organic shapes eg broken handles, hooks, housings etc, thus avoiding having to fully design stuff in CAD. For larger components such as my throttle body assembly, I will be better off sticking to conventional CAD. Must say, I'm somewhat less than surprised at this finding.

Certainly, I'm clearly not going to be able to create a meaningful engine and throttle body model that I can sensibly manipulate within Fusion 360, so for now the scanner will go back in its box while I stick to CAD.

Not vastly surprised or disappointed but it's good to have some clarity as to whet this is good for. And yes, I wouldn't have bought this if it hadn't been for the "season of giving".

No comments:

Post a Comment