I've ordered an MF18 finishing tap but short of buying both a roughing and a finishing tap, I'll need to rough out the thread on the Bantam. This will be my first internal threading operation.

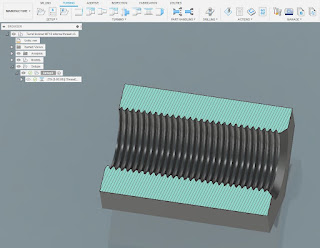

Firstly, let's create a CAD model. This is a 1-1/4" hex body with a 17mm bore, 'cos that's what I've got. That's a little under 100% thread but it will be more than sufficient.

And the toolpath. As the insert tip is 15mm from the back of the toolbar and the bore is only 17mm, I don't have much room for retract and clearance moves. Ideally I'd have some 11mm sized inserts but I'm not about to buy another boring bar and inserts.

No comments:

Post a Comment