First, let's finish connecting up the monitor. The bracket seems to be just about up to the job now that I've fitted an additional brace to make it more rigidly attached to the enclosure. And now I have 3m long cables for the USB, HDMI and mains, they actually reach to the controls.

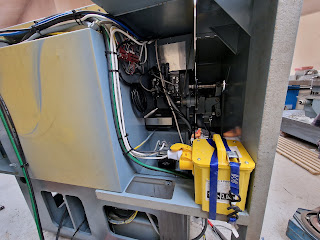

There's no simple means of fixing this to the chassis, as it's intended to be a portable site transformer. However, I have no pride, so one of these strap things will do the business. Last thing I want is somebody (most likely The Stupid Fat Guy) catching it in passing and it ripping the cables out of the cabinet.

Wiring up and plumbing up the coolant pump and its associated reservoir tank.Mounting and connecting up the monitor and mouse/kbd.Installing the 110V transformer (required for the hydraulic solenoids).Connecting up the internal (IP66) lights.- Making up some form of tool touch-off probe for tool length / offset etc measurement.

- Sealing the headstock / bed covers to the enclosure.

- Cleaning up (and polishing?) the front and tailstock windows.

- Checking out / replacing the Meanwell PSUs that seem to be tripping the RCD. Or wiring up a 240V isolation transformer on the main incomer.

- Machining several toolholders down from 20mm to 3/4" height so that the tool tip is at centre height (part of this machine's imperial legacy).

No comments:

Post a Comment