The Z axis ballscrew is about 1m long, yet it needs to be around 800mm. Time for some surgery. That's a 1m steel ruler alongside it. Forgive the state of the desk - clearly time for one of my periodic blitzes.

Mark the position for the cut with some tape - and cover the ballnut and the rest of the ballscrew to keep grit at bay.

There. Angle grinder.

Mount in the lathe, with crappy packing pieces to prevent it whipping and becoming bent. I'm not about to remove the ballnut just for this operation.

Turned down and grooved to take a circlip. I don't have a narrow grooving tool, so am using a 3mm parting tool.

Sorted:

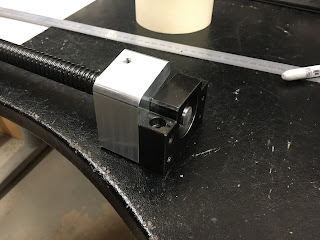

Fits inside the free (floating) bearing housing.

Now let's see about mounting it to the main body of the machine. Exactly where do the mounting holes need to go?

No comments:

Post a Comment