Welcome back.

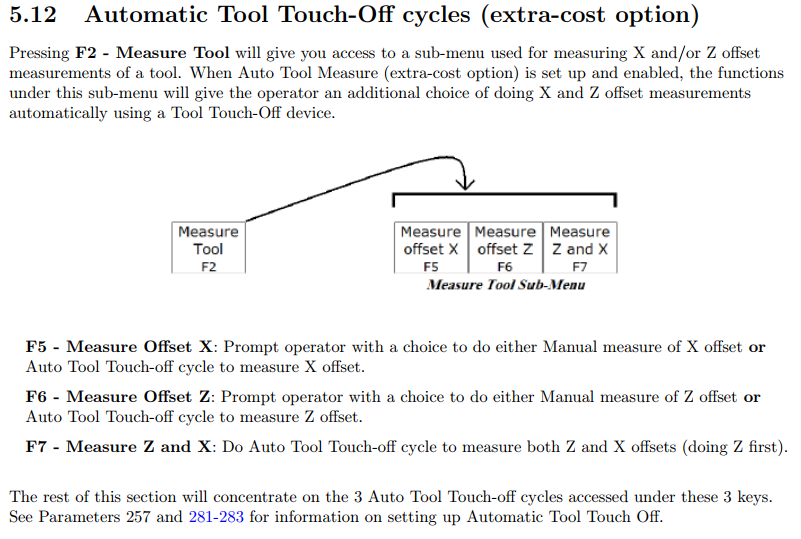

Much of the Xmas break has been taken up with endless shopping excursions, overconsumption, sitting on our arses etc etc. The actual number of workshop hours has been minimal, with most of that taken up with the tool touch-off issues I found within the Centroid software. Time to change that!

My cunning scheme for using the DIYO touch probe on the Tree sort of worked out but it's a bit fraught when it comes to turrets spinning, boring bars and LH tools all moving in different directions. One of the main reasons for taking this unconventional approach was the difficulty mounting the probe in the spindle, mainly due to the fact that my the chuck that currently fits is the Kitagawa hydraulic 3-jaw, which in turn has a very limited (~2.4mm) movement on each jaw.

I'm not planning on moving the jaws every time I want to touch off tools, hence a system that doesn't mount on the chuck.

There are some useful videos on the Haas website and of those, the lathe "Tip Of The Day" (TOD) videos contain some useful content for the likes of me, learning the CNC lathe ropes. Here's one that took my fancy - a stepped conical mount for a chuck-mounted lathe tool probe. This accounts for the fact that many hydraulic chucks have very limited jaw movement by incorporating many small steps in the diameter. No matter what the current jaw position, this should fit.

My chuck seems to manage about 2.4mm movement between open and closed, so steps of 2mm might work. Furthermore, I have some 70mm diameter 6082T6 in the box.

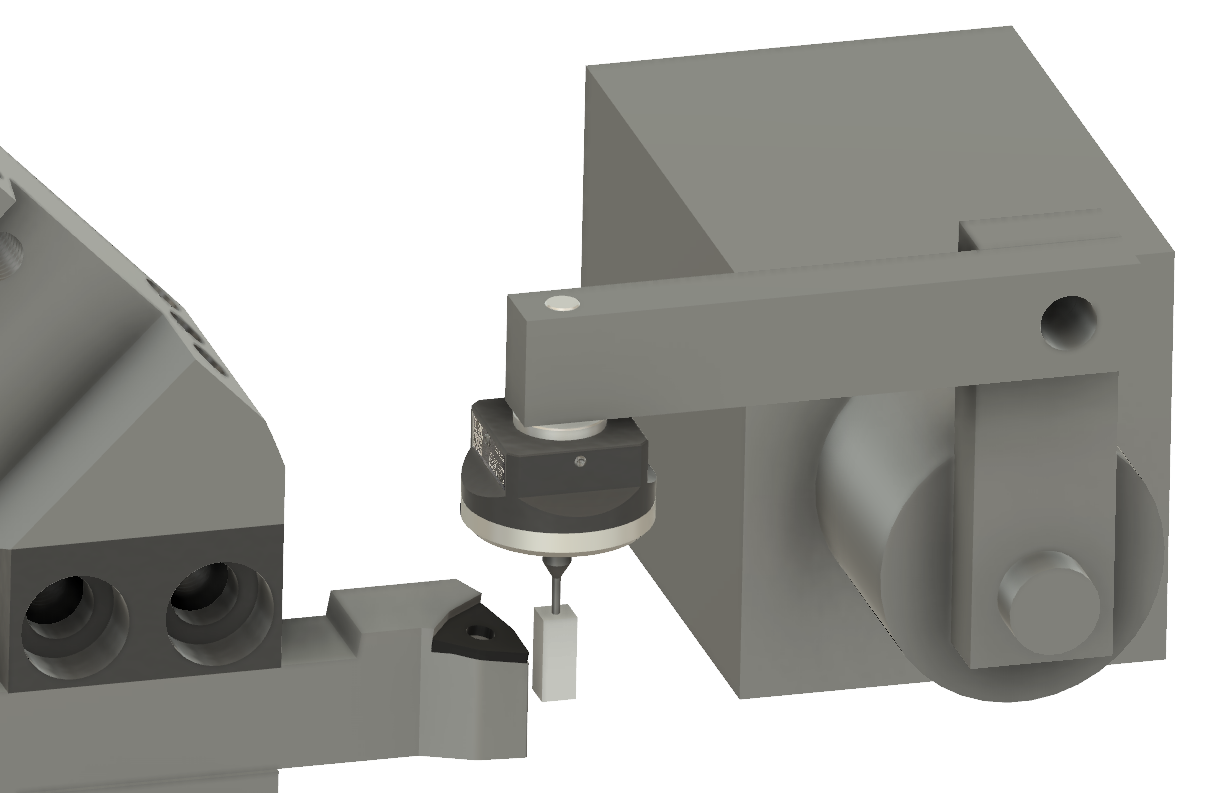

So let's model something up for my machine. The DIYO probe has a 6mm dia shaft and I need some meat for a grub screw as well as needing to avoid any deep grooving - typically the MGT tools I am using have a reach of around 18mm. This revolved section looks workable without getting overambitious. I used the Fusion 360 parameter table to drive the step length and radius increments:

I should be able to machine the stepped conical section using a VNMG insert and groove the necked down section using a KGMN200 (2mm) grooving / parting tool. I have the polished, uncoated (H01) flavours for use with loominum.

This should work:

Will the chuck be up to the job? With the acetal I used for my pawn test piece, the runout is pretty reasonable - about 20um.

I need about 70mm from the front of the stock. This leaves some safety clearance.

But hold on. The runout is more than just visible. The fucker is a major imbalance issue, or would be if the Tree didn't weigh several tonnes. Try as I might, there is no consistent way to clamp down on this stock to give an acceptable level of runout. I can tap it with a mallet so that the runout is brought to an acceptable level. But alarmingly, this doesn't require much of an impact. Put it another way, the stock is far from secure in the chuck.