I bought a cast iron backplate for the Tree from ebay, as this was the only example I could find. My hope was that I'd be able to bodge it so that it would allow me to fit my collection of D1-3 "Camlock" chucks, faceplates etc to the Tree rather than have to fork out for a whole new set. It may turn out to be usable in some form but there's clearly not enough meat on it to be able to use it for an A2-5 to D1-3 adaptor as such. I'm going to have to make my own from barstock.

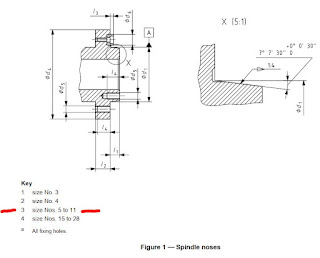

Let's dig out the spec for the A2-5 and D1-3 spindle noses. They are both specified in BS ISO 702 (parts 1 and 2).

They are both conical couplings but the A series use bolts, while the D1 series use cams to hold the chuck in place.

- A1-x series have 2 bolt circles

- A2-x series have one (outer) bolt circle.

- The second number denotes the size (diameter).

- They all have 7.125 degree cone angle (1:4 taper, tangent 1/8)

- Mine is an "A2-5" ie one bolt circle and 133mm diameter.

Here are the cams. The form on the LHS is the "size 3" used on the D1-3.

CAD modelling:

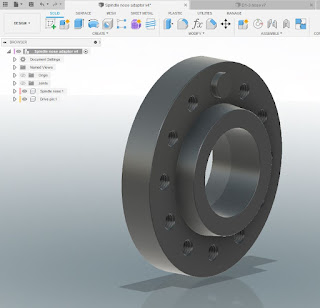

Let's create something to work with. To start with, the A2-5 spindle nose used on my machine. Note that in my case, I have 7/16" UNC threads, not M10. Other than that, the dimensions all seem to agree.

Now for the "standard" D1-3 spindle nose. This is what my chucks etc would expect to encounter eg on my Bantam.

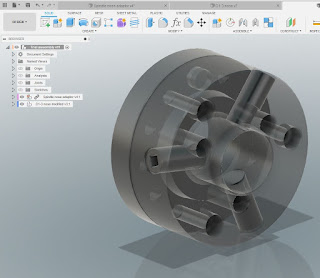

Clearly when you mount the D1-3 nose on front of the A2-5 nose, more meat needs to be added to accommodate the taper nose of the A2-5. Also, the A2-5 fixing bolts would fall outside the D1-3 profile, so the diameter will need to be increased. At this point, it's no longer the "standard" spindle nose, so I have freedom to redesign as required. This also includes the cams, which need to be lengthened. And I can change / move the retaining screws.

Here we go - rear view:

Front view, mated with A2-5 spindle nose:

No comments:

Post a Comment