I modelled the assembly up the other night when I was laid low with a buggered back (emptying cement bags). The required part needs to be reasonably robust - and simple so that it is not going to take me all month to make it.

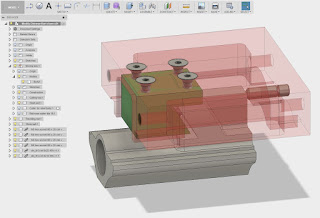

This is a drawing that shows the (grey) travelling nut and the (brown) moving jaws. The green part is the bracket I propose to make from a piece of steel. It will be held in place by four M8x25 CSK bolts. The hemispherical element will sit in a mating depression in said bracket - I'll grind a 16mm steel ball down to size.

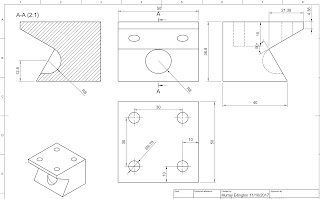

The bracket is relatively simple, although the 60 degree face will be a bit painful to machine. This is what the bracket itself will look like:

That's something to get stuck into tonight if my back doesn't complain too much.

Managed to find a piece of 2" x 2" steel. But my drawing calls for 2" x 2-1/4" x 55mm. Call me a lazy bastard - or even a fat, lazy bastard if you like - but I prefer economy of movement and effort, so how about modifying the dimensions to 2" x 2" x 57mm? And while I'm at it, I can't be arsed to attempt to machine out a 60 degree angle without a dovetail cutter And even if I did, I wouldn't look forward to the job.

So instead, I'll change the steel bracket to feature simple 90 degree angles:

Giving an assembly that has similar function but less fuss and ballache:

I think we'll find that a sight easier to flash up:

I prefer an easy life but I reckon it's also called being a good engineer. Keep it simple but achieve the required function.

Here we go. Chop chop:

I have this 3" boring head which fits the BP. But no cutters - a bit of a flaw in the plan perhaps.

But I have my BAP300 16mm indexable cutter. The shaft is a bit on the unnecessarily long side but it will do. It doesn't enhance the surface finish but won't affect the final function:

So there's the stock faced off to size. Now for the 60 degree notch.....

No comments:

Post a Comment