Phew. Finally got the servo drive working again. In the end, I merely had to replace the burnt out resistors in the step and direction optos. I previously desoldered the buggered 75ALS174 line driver device. As I don't anticipate any need to use the encoder feedback outputs from the drive back to the Acorn, I left the device position unpopulated on the PCB. There is no means of monitoring whether it's there, so the drive works fine without it. All is well now unless you remove the housing and see the abortionate bodge I left behind. Best not to do that.

So, having finally repaired the trail of destruction left by The Stupid Fat bloke's ham fisted attempts at connecting up the servo drive to the Acorn controller, I can now get to the bottom of the myriad parameters that need to be set up for correct operation. Some of these reside in the servo amp itself and others within the Acorn, which are best configured using the Acorn Wizard.

Parameter settings:

I have to take account of a few factors:

- The reduction ratio due to the timing belt drive, with 34t driver and 60t driven pulleys.

- The harmonic drive is a nominal 50:1 - but in the arrangement I've chosen, the effective ratio is actually 51:1. That's the sort of trap you could easily fall foul of.

- It's possible to set the number of steps per rev within the servo drive, also taking account of both the belt and harmonic drive. The manual is cryptic in places - nothing as powerful as the Chinglish I encountered in the Newker "manual" but still lacking explanation or examples to clarify your understanding. Some experimentation is required, unfortunately.

As noted above, the effective ratio for my setup is actually 51:1.

So the overall reduction due to the belt and harmonic drive is

So the overall reduction due to the belt and harmonic drive is

n = (34/60) x (1/51) = 17/1560

There's a box in the wizard where you can enter these values:

This how it's supposed to work:

Using the calculation in the table above, using the 17:1530 ratio at play here, I get

With effectively 4 pulses per clock cycle, you can see how the a "1000 PPR" pulse frequency from the Acorn would work with this.

Good to have a sanity / cross check giving results that make sense.

- Pn203 = 36000

- Pn202 = 5898240

- Pn203 = 4000

- Pn202 = 65535

With effectively 4 pulses per clock cycle, you can see how the a "1000 PPR" pulse frequency from the Acorn would work with this.

Good to have a sanity / cross check giving results that make sense.

The next "reference unit" screen caused me some confusion. I played with this a while and finally left it as shown. Somehow, the reference unit couldn't be reduced much below 0.001 degrees(!) from its initial 0.0001 degree setting. There's not mention of why this would be but it must be a result of having a 16 bit encoder. The error message when you enter a wrong value (0.1 degrees, sir?) is one of those particularly unhelpful "computer says no" ones that leave you none the wiser.

This one puzzled me too.

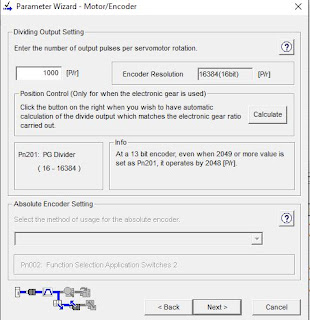

I seem to have told it that I want 1000 PPR here. However, it looks to me as if it's talking about the encoder output from the drive (to the external system controller), for which I have no use - nor in fact any line driver to generate the signal in the first place! Most of these drives are able to generate a virtual encoder signal based on the motor encoder so that the external system controller can close the loop. The resolution of that output can be different to the native resolution of the 16 bit encoder within the motor - ie 65535 PPR.

As ever, you can only assume the guy(s) who wrote this knew what they meant....

So here are the final parameter values, as reported by the parameter editor in the SigmaWin+ software:

Finally, the resolution setting in the Acorn wizard matches the 1000 PPR value set up by the Yaskawa servo wizard.

Feed rate limitation:

Note that the "max pulse frequency" value set by the Acorn wizard limits the maximum feed rates. Obviously if you have a very high resolution (PPR) set up in the servo drive, you will find that the maximum achievable feed rate is going to be slow. I previously reduced the frequency from the original value of 400kHz to the lowest setting of 100kHz so I could drive the Chinesium (Leadshine clone) stepper drive without missing (all) pulses. The wizard does some basic calculations to prevent you setting feed rates that can't be achieved. These appear to be little more than a very simple division of the max frequency by the resolution, which is fair enough.

None of the 4 servo drives have any obvious limitation that prevents running them on the maximum setting of 400kHz, so I've reverted to that value. This allows reasonably fast feed rates, making best use of the available 3000rpm from the motor. No self respecting Youtube Warrior would be seen dead using anything other than blistering feedrates obviously.

That it?

So I seem to have finally got the 4th axis working with the correct scaling, making sensible use of the available performance.

Acid test of the parameter values is running the axis over a large number of full revolutions (10 is good) to check that there is no creep of the zero position. This confirms the values work as intended.

One final step - let's try the autotuning function. That will have to wait for the moment....

No comments:

Post a Comment