Here's the (mesh) stock model from the previous setup being imported for use as the stock:

Finally, this is what is shown as the stock. Looks good to me.

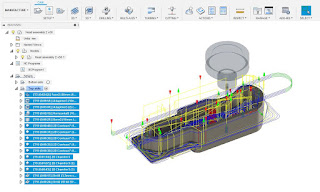

Here's the CAM for the top side:

Pretty fiddly picking up the stock origin. I placed this on a machined corner, noting that the flat surface I was picking up on was 0.47mm left of the origin:

I need to get the original position right to avoid misalignment between the top and bottom operations. I've got a 20mm gauge block up against the end of the machined face (X axis). And I can pick up the Y and Z axes from the faces of the spacer plate.

Right, that worked out nicely. No tool breakages so far....

The witness mark between the top and bottom setups is minimal. It's less than the 10um or so I can measure with a std digital caliper.

Now for a cover....

Retrofitting 1983 Shizuoka AN-SB CNC milling machine, Bridgeport mill, Colchester Bantam lathe and 1982 Tree UP-1000 CNC lathe with modern controls - and other workshop stuff

Subscribe to:

Post Comments (Atom)

End stop for drawer self closing damper

Que? We have a couple of these pull out spice drawers in the kitchen. They are 150mm / 6" width and are basically filling in a 30cm gap...

-

Setting up the servo tuning(?) software: Having spent a couple of hours yesterday pratting about with the PID controllers for the X and Z ax...

-

Right, so having gone through the motions with the X axis (cross slide), I should now be able to set up the Z axis (longitudinal) encoder an...

-

The bearing arrived as expected this morning. Took a few minutes to make up a 42 x 25.5 x 7mm thrust washer, then fitted the bearing and was...

No comments:

Post a Comment