WTF?? I have a Korloy AMCM3050HS cutter with pukka APMT1604PDER-M2 inserts, yet I am getting a completely shitty surface finish. It's obviously rubbing instead of cutting. I used a fresh set of inserts, yet the edge looks unhappy after just one pass of only moderately heavy cutting. WTF???

Here's the edge of the insert. Not easy to photograph using an iPhone but you can just about make out the suboptimal end result.

Let's do a trial cut again, at 1200rpm.

The photo hardly does justice to the crap finish. Enabling coolant half way through made no obvious difference. This is rougher than any self-respecting bear's arse.

By way of a sanity check, here's a slot made by a Mitsubishi BAP390 series indexable cutter (16mm dia) in the same machine and workpiece at 5000rpm. It's a different result altogether. And yes, those are genuine Mitsubishi inserts and a genuine Mitsubishi body.

What's going on?

There's no such thing as a universal fit AP** insert, it seems. And even within the range of one manufacturer such as Korloy, there is a bewildering range of insert geometries, not just the chipbreaker shape. What I didn't say above is that the APMT1604PDER are made by Mitsubishi. Clearly the APMT1604PDSR inserts recommended by Korloy are subtly(??) different.

Here's what Korloy recommend for this cutter:

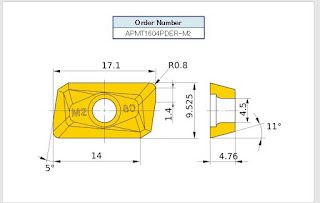

And the Mitsubishi insert that is apparently functionally similar:

You can even download a STP file for the insert model. This shows the 15 degree clearance angle at the bottom of the insert, for instance. Ideally I'd also have a model from Korloy to do a comparison against. However, you can imagine that if the Korloy holder lacked at least 15 degree helix angle, the Mitsubishi insert would rub. Is this what is happening? Doesn't appear to be the case - visual inspection shows a clear clearance angle. However, the inserts really don't seat properly in the cutter body.

For now, I'll order up some of the official Korloy inserts - one set each of H01 (uncoated, for loominum) and PC5300 (for steel). The MA suffix denotes the sharp chipbreaker geometry and ideally I'd manage to source some light duty, sharp inserts for steel but Aliexpress didn't offer me any.

These will do for the loominum cutting inserts:

Conclusion:

So, the lesson seems to be to look very carefully at the manufacturer's data for the cutter body and be careful to obtain only the recommended inserts, rather than some generic part, even from a reputable manufacturer. Or at least I think that's the lesson here. When I get the new inserts in a few weeks time(?), I'll be able to confirm that hopefully. Meanwhile, for facing off and squaring up the stock for the yoke, I'll have to use something else, such as a solid carbide or HSSCo cutter. Perhaps I should have used the lathe after all.....

No comments:

Post a Comment