Differential line driver module:

The position sensors I used are simple open collector devices, typically used to acquire crank position information for engine management applications. In my application, the signals need to be fed into the CNC controller which expects differential signals. The CNC controller uses a AM26LS32A Quadruple Differential Line Receiver from TI / Motorola etc. Although it may be possible to frig the interface to sort of make it work with single ended inputs, it's going to be a bit dodgy to go that way.

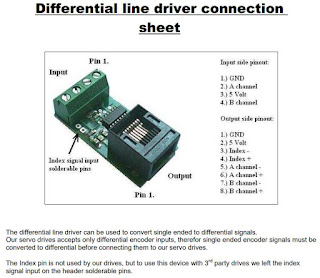

My servo drives were supplied by CNCDrive.com in Hungary. As those drives also require a differential encoder signal, they sell a simple converter module for 4.50 Euros. They look just the ticket:

I've ordered 2 of these and will fit them in the head casting, as close to the sensors as possible, to make the most of the improved noise immunity offered by the differential signals. They will take a week or so to arrive but I'm not expecting to be doing any rigid tapping before then...

Retrofitting 1983 Shizuoka AN-SB CNC milling machine, Bridgeport mill, Colchester Bantam lathe and 1982 Tree UP-1000 CNC lathe with modern controls - and other workshop stuff

Subscribe to:

Post Comments (Atom)

End stop for drawer self closing damper

Que? We have a couple of these pull out spice drawers in the kitchen. They are 150mm / 6" width and are basically filling in a 30cm gap...

-

Setting up the servo tuning(?) software: Having spent a couple of hours yesterday pratting about with the PID controllers for the X and Z ax...

-

Right, so having gone through the motions with the X axis (cross slide), I should now be able to set up the Z axis (longitudinal) encoder an...

-

The bearing arrived as expected this morning. Took a few minutes to make up a 42 x 25.5 x 7mm thrust washer, then fitted the bearing and was...

No comments:

Post a Comment